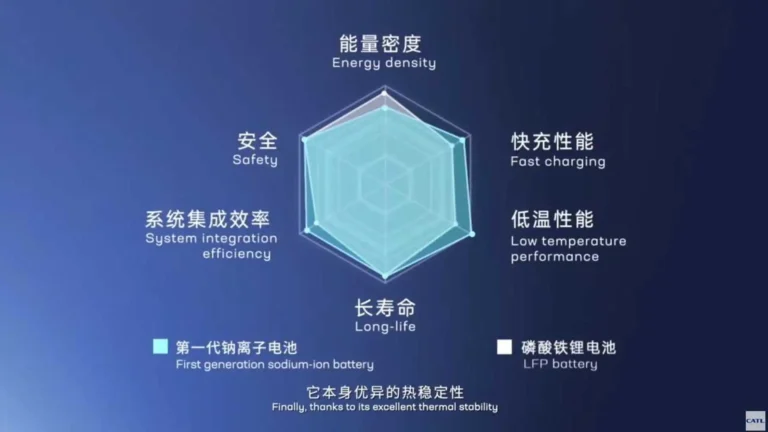

Sodium-aluminum batteries, also known as sodium-ion batteries, are a type of rechargeable battery that uses sodium ions to store and release energy. These batteries are similar in structure to lithium-ion batteries, but they use sodium ions instead of lithium ions.

One of the main advantages of sodium-aluminum batteries is that they use abundant, low-cost materials, making them potentially cheaper than lithium-ion batteries. Sodium and aluminum are both widely available, with sodium being the sixth most abundant element on Earth and aluminum being the most abundant metal. Sodium-aluminum batteries have a higher energy density than some other types of batteries, such as lead-acid batteries. This means they can store more energy in the same amount of space.

However, sodium-aluminum batteries are still in the early stages of development, and there are some challenges that need to be overcome before they can be widely used. One of the main challenges is that sodium ions are larger than lithium ions, so it can be more difficult to move them through the battery’s electrolyte. This can result in lower power and energy density compared to lithium-ion batteries. Additionally, the use of aluminum can cause the battery to swell and degrade over time, reducing its lifespan.

Breakthrough News 2023

US researchers have designed a molten salt that could potentially reach an energy density of up to 100 Wh/kg at a cost of $7.02/ kWh. The battery uses an aluminum cathode that charges quickly and reportedly enables a longer-duration discharge. Based on an anode made of molten sodium (Na) and a cathode made of aluminum (Al) and sodium tetrachloroaluminate (NaAlCl4).

They described the novel battery as a low-cost, grid-scale solution for long-duration renewable energy storage and said the use of NaAlCl4 offers extra accessible capacity hidden in acidic chloroaluminate. They said the proposed battery chemistry relies on the sixth and second most abundant elements on Earth.

This enables higher specific capacity and average discharge voltages than previous Na-Al batteries, utilizing two distinct cell reaction mechanisms in one battery,” the researchers said, noting that this second reaction, on top of the neutral molten salt reaction, is the crucial factor for the device’s higher voltage and capacity. “Specifically, after 345 charge/discharge cycles at high current, this acidic reaction mechanism retained 82.8 percent of peak charge capacity

In a nitrogen-filled glovebox, the researchers constructed Na-Al full cells in a discharged state, which they sealed hermetically using stainless steel endcaps and eight screws tightened in a star pattern. The solid-state electrolyte of the battery permits only sodium to move through during the charging process. The flat cell design of the system allows for a thicker cathode to increase the cell’s capacity. The researchers utilized this design to showcase a triple capacity cell that was capable of sustaining a discharge for 28.2 hours under laboratory conditions.

The research team discovered that the battery can achieve a high areal capacity cell of 138.5 mAh cm−2, even when subjected to a high current density of 4.67 mA cm−2. They anticipate that the battery could potentially have an energy density of up to 100 Wh/kg, with a low cost of $7.02 kWh. Another advantage of the new battery design is that it eliminates the need for scarce and expensive nickel, while maintaining battery performance. According to Li, the aluminum cathode charges quickly, which is essential for enabling longer discharge duration. The team presented their battery technology in a recently published article in Energy Storage Materials titled “Unlocking the NaCl-AlCl3 phase diagram for low-cost, long-duration Na-Al batteries.” The researchers believe that the new molten salt battery design can charge and discharge faster than traditional high-temperature sodium batteries, operate at a lower temperature, and maintain excellent energy storage capacity.