How these chemistries differ in relation to EVs and energy storage

What are the advantages and disadvantages of LFP type batteries versus NCA type batteries

Summary

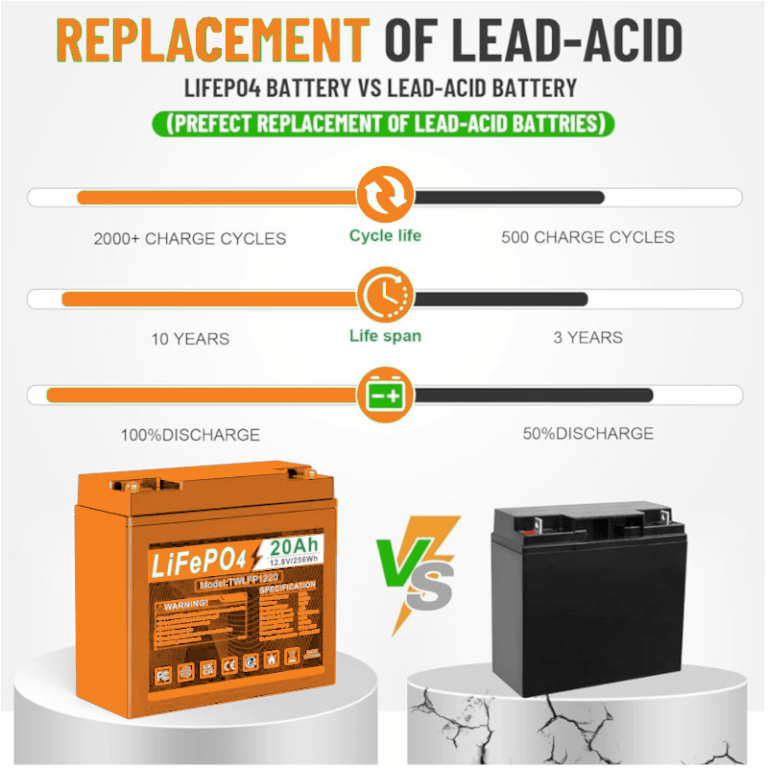

Lithium Iron Phosphate (LFP) batteries are gaining momentum in the electric vehicle industry. This video compares LFP chemistry, like CATL’s, to NCA chemistry used by Tesla. LFP has a slower diffusion rate and poor electrical conductivity, but innovations have improved its performance. NCA has higher energy density but is less stable and more prone to thermal runaway. At the pack level, LFP performs better due to its durability, requiring less protection. Chinese producers prefer prismatic cells for LFP batteries to compensate for lower volumetric energy density.

Highlights

1:20 🕐 LFP batteries are gaining popularity for electric vehicles and grid storage.

2:50 🕐 LFP and NCA have different crystal structures, affecting their performance.

6:40 🕐 LFP initially had issues with conductivity and ion movement, but innovations improved its performance.

11:55 🕐 NCA has higher energy density, but its crystal structure is less stable and more prone to thermal runaway.

16:20 🕐 At the pack level, LFP performs better due to its durability and requires less protection.

19:40 🕐 Chinese producers prefer prismatic cells for LFP batteries to compensate for lower volumetric energy density.

23:10 🕐 The LFP chemistry used in Tesla’s Standard Range Plus Model 3 has limitations due to volumetric energy density.

Key Insights

💡 LFP batteries have a slower diffusion rate due to the 1D tubes that restrict the movement of lithium ions. This affects their charging and discharging speed.

💡 LFP’s crystal structure provides stability and prevents collapse when lithium ions leave. However, it also results in poor electrical conductivity due to the spacing of iron atoms.

💡 Innovations such as smaller particle size, carbon coatings, and doping have improved the electrical conductivity and lithium capacity of LFP batteries.

💡 NCA batteries have higher energy density due to their 2D planes that allow for easier lithium diffusion. However, their crystal structure is weaker and more reactive, leading to safety concerns.

💡 LFP batteries have a flat voltage profile, which provides steadier voltage and current. This has advantages for hardware and software engineers but can be challenging for vehicle manufacturers used to NCA batteries.

💡 At the pack level, LFP batteries perform better due to their durability, requiring less additional weight and volume for protection. This helps offset their lower gravimetric and volumetric energy density.

💡 Chinese battery producers prefer prismatic cells for LFP batteries because they fill rectangular packs better, compensating for the lower volumetric energy density of LFP.